Category Archives: Blog

What is the external packing?

The external packing can prevent the wall panels from being damaged through transportation, specially for LCL shipment or air transport. The cost of external packing is an extra cost (the cost of internal packing is included in the panels). We offer 2 selections for external packing:

Selection 1 (recommended). – Made by professional packing company, the case (the image shown in below) is customized for LCL cargo, which can fit within 60 wall panels in standard size(1220mm*2440mm*15mm). this costly full case is made from plywood with aluminum alloy armet, it can well protect the wall panels from collision through ocean transportation. However, this is not our default package for LCL cargo, it is payable selection, and the cost is USD120 each.

Selection 2 (not recommended). Factory customized packaging box – Made by our worker, using plywood and mdf, it may not strong enough, the cost is USD 50 each.

New recommended spray painting method for 3d wall panels

New recommended spray painting method for 3d wall panels:

Step 1. Ensure that the routed 3d wall panels meet the next adjoining panel. Leave a gap of about 1-2mm in between panels for fillers.

Step 2. Use “polyester putty” (commonly used in vehicle spray painting industry) as filler for gaps, points and nail holes.

Step 3. Apply the putty with a spreader, ensure all gaps, joints and holes are joints and holes are fully filled. Allow drying time in between application for putty to be fully settled.

Step 4. Sand off the excess filler covering gaps, joints and nail holes. Do a light and fine sanding over the entire surface of the pre-primed 3d wall panels as preparation to receive paint.

Step 5. Thin layers of paint are to be applied in between drying intervals.

Step 6. Advisable to engage skilled professional spray paint applicator for best result.

New Recommended Installation Idea for 3d wall panels

New recommended installation idea for 3d wall panels:

Step 1. Ensure wall surface is smooth and levelled, ideally to have a plywood backing or plywood strips nailed directly onto concrete wall prior to installation of the panels.

Step 2. Pre-cut the 3d wall panels to fit wall dimensions using traditional table saw commonly used by furniture makers and carpenters.

Step 3. For trimming or cutting of corners or opening use a electric jigsaw with saw blade suitable for wood cutting.

Step 4. For added strength, apply spots of bonding adhesive (commonly used in woodworking industry) onto the back of the 3d wall panels before securing.

Step 5. For installation of more than one panel, ensure that the routed patterns meet the next adjoining 3d wall panel. Leave a gap of 1-2mm for fillers before paint application.

Step 6. Secure the 3d wall panels by using air-compressor operated fine nails or staplers directly onto plywood backing.

Recruitment Information 2013

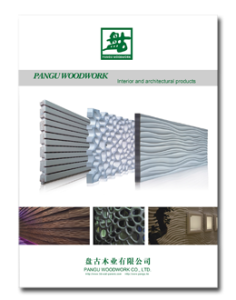

Pangu is a leading manufacturer of architectural wall panels in China, we are focuses in developing exciting interior environments through the application and installation of 3d wall panels. By the end of 2012, Pangu has over 20 distributors around world, pangu panels has sole to over 40 countries.

In order to explore the global markets and enlarge our production capacity to meet the needs of increasingly developing requirement of our customers, we have a number of opportunities for all levels, backgrounds and ambitions, we sincerely invite the talents to join us!

The following are the positions that we are looking for:

Sales department (2 positions): 1) Undergraduate or higher degree; 2)CET-6 certificate, TEM-4 or higher certificate; 3) be good at communication with customers, well in spoken English or writing.

Factory workshop (12 positions for sanding workers, 1 position for painter, 2 positions for packing workers): Relevant working experience is preferred.

Applying position: Please send your resume to: hr@pangu.hk

New screen wall designs in 2013

Another two new screen wall designs coming – As a gift for 2013 Chinese new year holidays, we are very pleased to introduce two new screen wall designs to our designers, both of them are really interesting and innovative.

Sometimes your eyes are cheated by what you have seen in your fist sight, we can find some examples from certain interesting paintings, pictures or art works, today we transplant this kind of idea into our screen wall designs.

, just let us take a look at the two new screen wall designs that we bring to you:

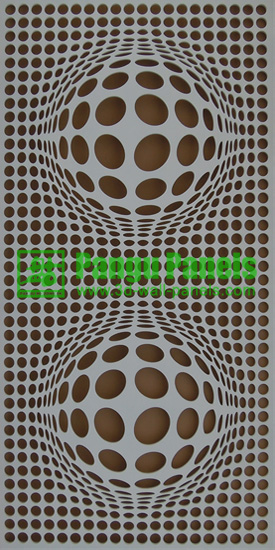

This new screen wall design is named GP4028, we all know that it is made out in a flat MDF panel, however, it appears like two balls are dragged out by external force, giving an 3d effect from the flat panel.

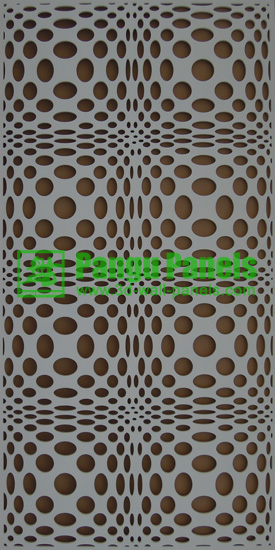

The design code of this new screen wall design is GP4029, the pattern looks moving vividly.

Looking for more interesting patterns on decorative grille panels.

Scan and save our website & contact information here!

Scan and save our website & contact information here!